Silinder Multi Cylinder Cone Crusher Si fudud loo shaqeeyo

Sharaxaada Alaabta

Xakamaynta Haydarooliga si loo hagaajiyo dekedda dheecaanka ah, fududahay in la shaqeeyo , Noocyo kala duwan oo qaabka godka hagaajinta saxda ah, badbaadinta wakhtiga iyo dadaalka.

Xakamaynta hydraulic "ka badan birta" ilaalinta, nadiifinta godka waxay yaraynaysaa wakhtiga hoos u dhaca waxaan sameynay dadaal weyn si loo hagaajiyo sifooyinka farsamada ee qaybaha korantada, sida jir, shafka ugu weyn, gears bevel, eccentric, iwm

Codsiga

Warshadda ciidda iyo dhagaxa, warshad isku-darka shubka ah, hoobiye qalalan, desulfurization warshad koronto, ciid quartz, iwm., Birta, dahabka, naxaasta iyo walxaha kale ee macdanta macdan; Quruurux, granite, basalt, limestone, quartzite, diabase iyo walxo kale oo aan bir ahayn.

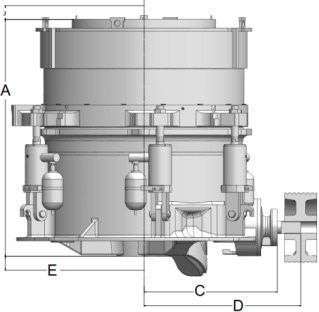

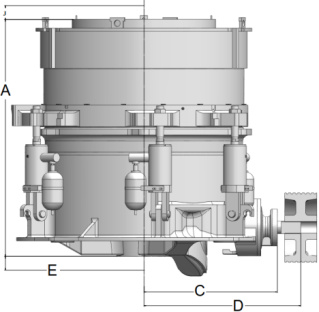

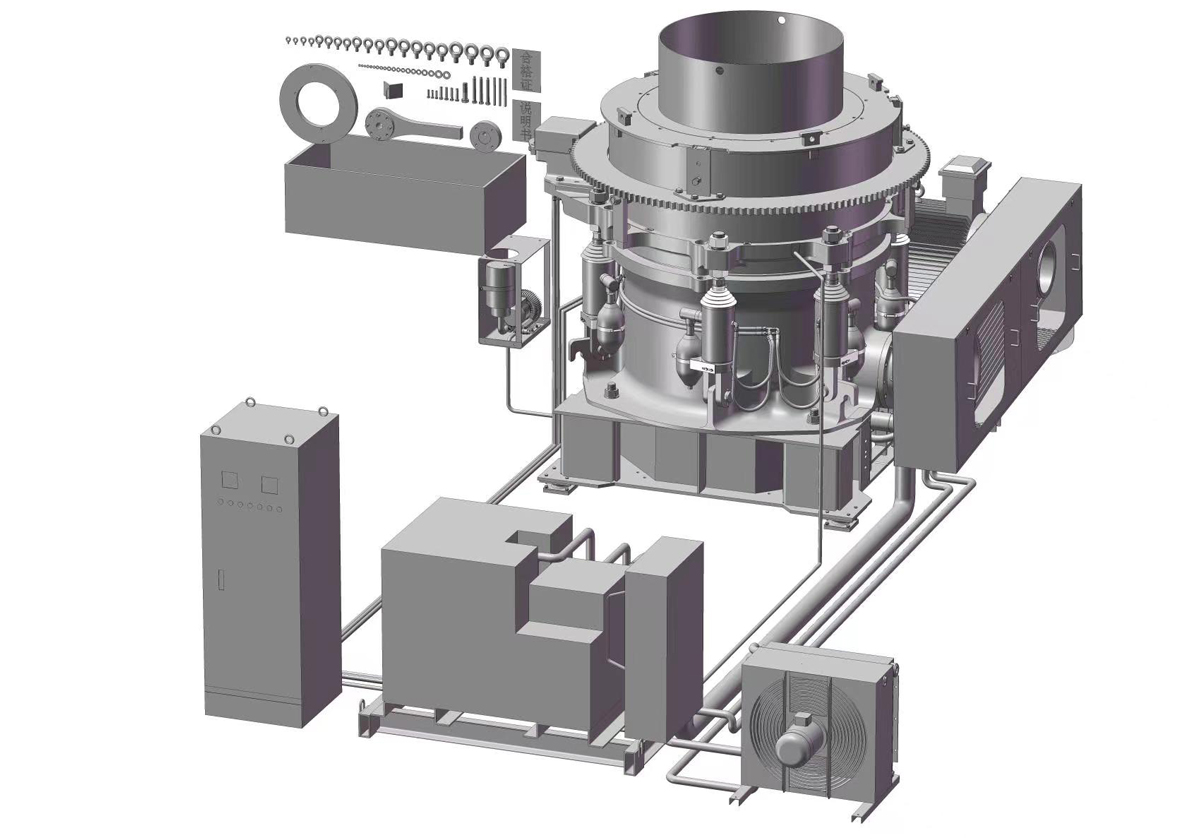

Muuqaal

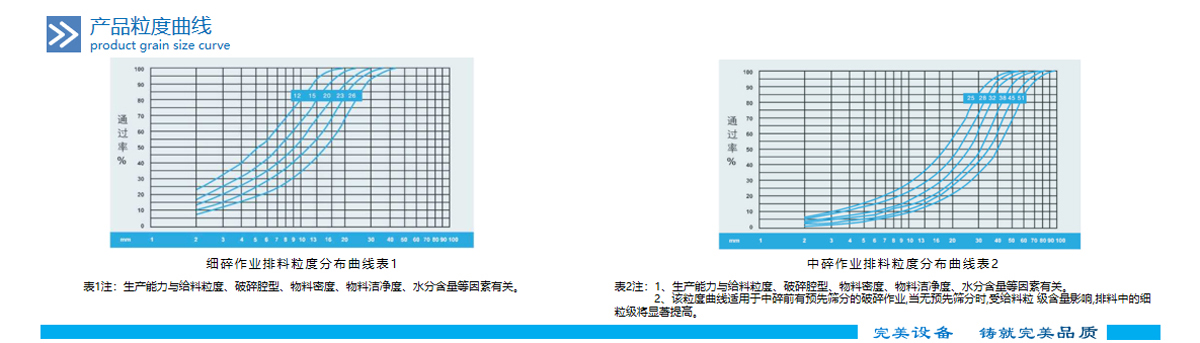

lebbiska cabbirka hadhuudhka

Mabda'a ah burburinta waa laminating, ma aha oo kaliya si wax ku ool ah loo yareeyo xirashada, dheereeyo nolosha adeegga ee qaybo ka mid ah, laakiin sidoo kale ka dhigi xisaab cube dhameysatay ee sare, irbado yar iyo alaabta flake, size hadhuudh dheeraad ah lebis, iyo daboolo baahida tayada sare leh. Iyada oo mabda'a shaqo ee gaarka ah iyo qaab-dhismeed la hagaajiyay, waxay leedahay awood qaadis xoog leh, awood weyn oo rakiban iyo awood wax soo saar sare leh.

Ilaalinta Hydraulic, saliidda saliidda

Dekadda laga soo daayo kontoroolka haydarooliga, ilaalinta culeyska xad dhaafka ah iyo ficilka nadiifinta godka, ka dhig qalabku si habsami leh oo badbaado leh, u yareeya wakhtiga dhimista iyo dayactirka, hagaajinta hufnaanta burburinta. Nidaamka saliidda khafiifka ah ee khafiifka ah, ayaa si weyn u wanaajinaya nolosha adeegga qalabka.

Kordhinta heerka Automation-ka

Nidaamka korantada ee Advanced PLC waa la isticmaalaa, waxay si joogto ah ula socon kartaa xaaladda hawlgalka, hawlgal fudud, ammaan ah oo la isku halayn karo; nidaamka hal-abuurka ah ayaa sidoo kale lagu dari karaa nidaamka xakamaynta xariiqda wax soo saarka si loo dhamaystiro nidaamka xakamaynta isku xirka.

Ujeedo badan oo mashiinka ah dayactir ku habboon

Kaliya beddelka xargaha iyo qaybaha kale ee la xidhiidha waxay samayn karaan beddelka qaabka godka, si loo daboolo shuruudaha dhexdhexaadinta iyo jajabinta ganaaxa. Qaab dhismeedka macquulka ah, hawlgal la isku halayn karo, kabka hawlgalka hooseeya, tayada sare ee alaabta la dhammeeyey.

Halbeegga Alaabta

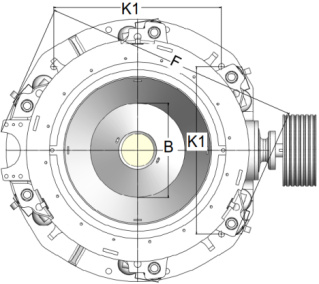

Qiyaasta Farsamada ee QHP500

| A | 2290 |

|

| B | 1535 | |

| C | 1760kii | |

| D | 2650 | |

| E | 425 | |

| F | 2730 | |

| J | 125 | |

| K1 | 1764kii |

| QHP500 Xadka Gudbinta | |||||||||||

| CSS mm | 10mm | 13mm | 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 45mm | 51mm | 65mm |

| Marmar t/s | 175-220 | 230-290 | 280-350 | 320-400 | 345-430 | 365-455 | 405-535 | 445-605 | 510-700 | 580-790 | 650-950 |

| qalooca miisaanka alaabta | |||||||||

| Qalooca qaybinta dareeraha hawlgalka godka caadiga ah | Qalooca qaybinta qulqulka hawlgalka god gaaban | ||||||||

| Nooca daloolka | CX | C | M | MF | Nooca daloolka | SC | SM | SF | SFX |

| Soo dayn baaxadda furan (mm) | 30-65 | 25-65 | 20-65 | 16-65 | Soo dayn baaxadda furan (mm) | 13-65 | 10-65 | 8-65 | 6-65 |

| CSS (mm) | 355 | 286 | 204 | 133 | CSS (mm) | 95 | 57 | 52 | 53 |

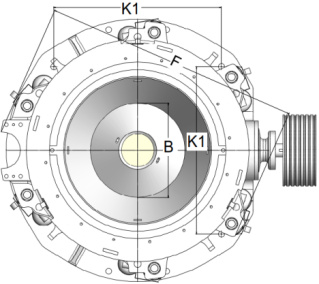

Qiyaasta Farsamada ee QHP400

| A | 2057 |

|

| B | 1308 | |

| C | 1645kii | |

| D | 2475 | |

| E | 240 | |

| F | 2370 | |

| J | 152 | |

| K1 | 1660 |

| QHP400 Xadka Gudbinta |

| ||||||||||

| CSS mm | 10mm | 13mm | 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 45mm | 51mm | 65mm |

| Marmar t/s | 140-175 | 185-230 | 225-280 | 255-320 | 275-345 | 295-370 | 325-430 | 360-490 | 410-560 | 465-630 | |

| qalooca miisaanka alaabta | |||||||||

| Qalooca qaybinta dareeraha hawlgalka godka caadiga ah | Qalooca qaybinta qulqulka hawlgalka god gaaban | ||||||||

| Nooca daloolka | CX | C | M | MF | Nooca daloolka | SC | SM | SF | SFX |

| Soo dayn baaxadda furan (mm) | 30-65 | 25-65 | 20-65 | 14-65 | Soo dayn baaxadda furan (mm) | 10-65 | 8-65 | 6-65 | 6-65 |

| CSS (mm) | 299 | 252 | 198 | 111 | CSS (mm) | 92 | 52 | 51 | 52 |

Qiyaasta Farsamada ee QHP300

| A | 1866kii | |

| B | 1078 | |

| C | 1347 | |

| D | 2023 | |

| E | 328 | |

| F | 2207 | |

| J | 87 | |

| K1 | 660 |

| QHP300 Xadka Gudbinta |

| ||||||||||

| CSS mm | 10mm | 13mm | 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 45mm | 51mm | 65mm |

| Marmar t/s | 115-140 | 150-185 | 180-220 | 200-240 | 220-260 | 230-280 | 250-320 | 300-380 | 350-440 | ||

| qalooca miisaanka alaabta | |||||||||

| Qalooca qaybinta dareeraha hawlgalka godka caadiga ah | Qalooca qaybinta qulqulka hawlgalka god gaaban | ||||||||

| Nooca daloolka | CX | C | M | MF | Nooca daloolka | SC | SM | SF | SFX |

| Soo dayn baaxadda furan (mm) | 25-65 | 19-65 | 17-65 | 13-65 | Soo dayn baaxadda furan (mm) | 10-65 | 8-65 | 6-65 | 6-65 |

| CSS (mm) | 233 | 211 | 150 | 107 | CSS (mm) | 77 | 53 | 22 | 25 |

Marka loo eego isbeddelada farsamada iyo cusbooneysiinta, cabbirada farsamada ee qalabka ayaa la hagaajiyaa wakhti kasta. Waxaad si toos ah noola soo xiriiri kartaa si aad u hesho cabbirada farsamada ee ugu dambeeyay.